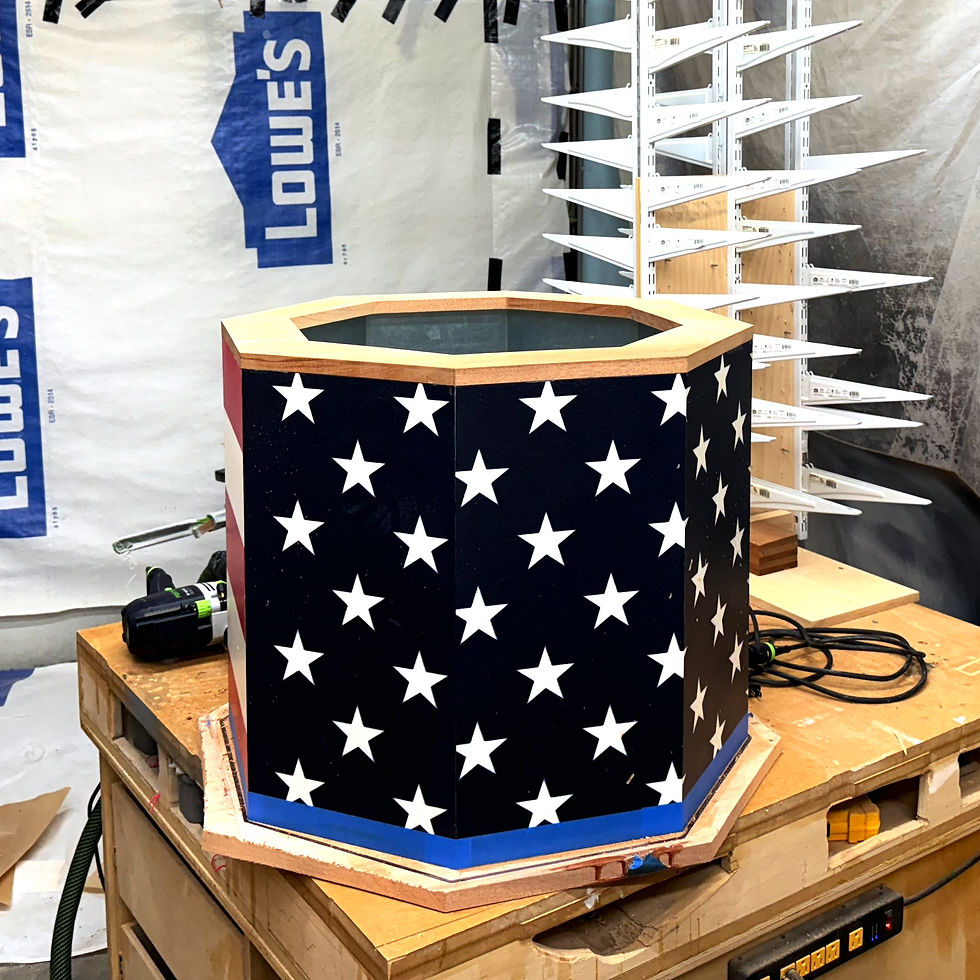

Main Component Complete!

- Mark Petrilla

- Oct 16, 2025

- 2 min read

The cooler itself is now complete! The only thing left to do is design and make the lid. That's no small task and my plan is to inlay this image below.

What did this stage cost?

The mahogany lumber for the based came in at $170.

The bolts and wheels came in at $20.00 + $56.99 respectively

Totaling - $246.99

What is the next stage?

Designing and building the lid.

Have any questions? Ask away!

Mark Petrilla, Gorilla Bark Studio's

Paying tribute to those who keep us safe.

Comments